柔性橡膠避震喉: silent hero in hydraulic systems

Imagine a world where machinery operates silently and smoothly, without the disruptions caused by vibrations and noise. This is not just a sci-fi concept, but reality for engineers designing modern hydraulic systems. At the heart of this silent operation lies a silent hero: the hydraulic system’s damping element known as a “flexible rubber damping ring.”

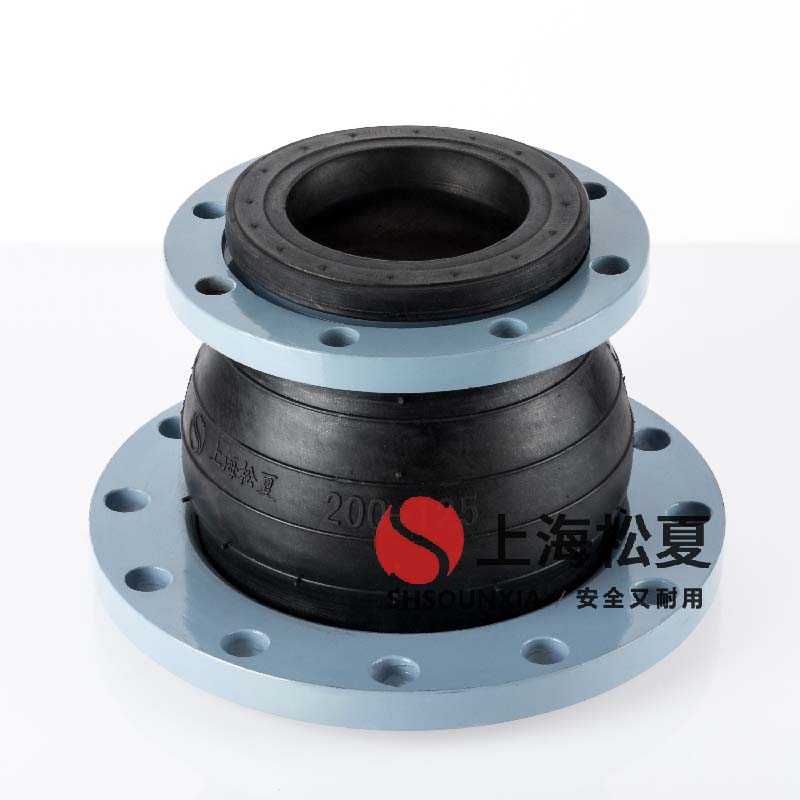

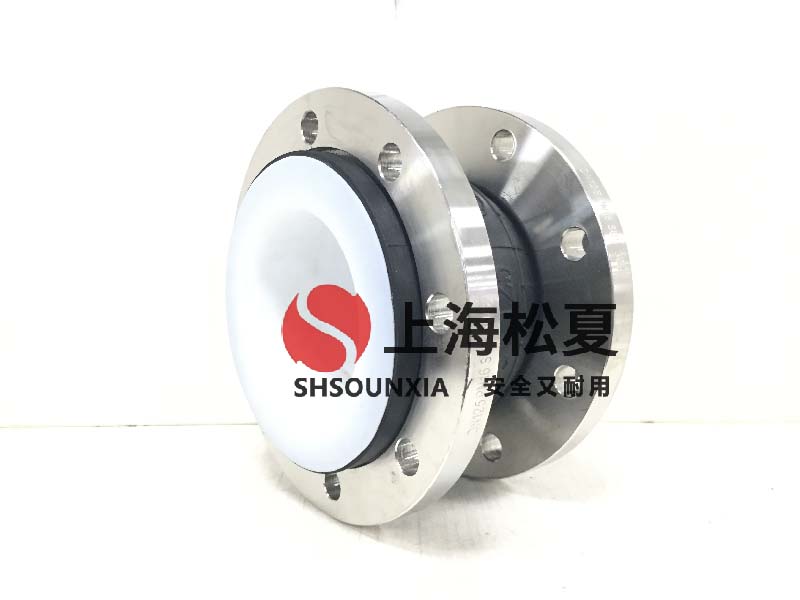

What is a Hydraulic Damping Ring?

A hydraulic damping ring, or flex rubber ring, is a silent dampener designed specifically for hydraulic systems. It absorbs vibrations, protects equipment from shock, and reduces noise, all without introducing any reciprocating movement into the system.

Why is it Better than a Spring?

While springs are a classic solution for vibration absorption, they come with their own set of limitations. Springs degrade over time, require lubrication, and can lead to excessive play and binding. In contrast, a flex ring provides a consistent damping force over its entire lifespan, requires no lubrication, and eliminates play entirely. It’s a maintenance-free solution that continues to protect your equipment long-term.

How Does it Work?

The flex ring sits between the pump and the machine, absorbing shock and distributing force evenly. Its rubberized material absorbs energy through flexing, converting kinetic energy into heat and sound energy, which dissipates quickly. The ring’s design allows it to absorb vibrations across a wide range of frequencies and amplitudes, making it effective in both machine start-ups and shutdowns.

Why Should You Choose Flex Rings?

-

Silence the Machine: The primary purpose of the flex ring is to absorb vibrations and reduce noise. This makes your machine quieter, reducing fatigue for operators and extending equipment life.

-

Longevity: Unlike springs, flex rings don, they’re built to last. The material is durable and wear-resistant, ensuring years of trouble-free operation.

-

Compatibility: Flex rings work with a wide range of hydraulic systems and components, making them a versatile choice.

-

Cost-Effective: While slightly more expensive than springs, the long-term savings in maintenance and replacement are offset by the higher efficiency of the system.

How to Install

Proper installation is key to getting the full benefit of a flex ring. Ensure that the pump and machine are aligned and free of debris. Apply even pressure during installation, and follow manufacturer guidelines for proper torque application. Proper installation ensures maximum vibration absorption and noise reduction.

In conclusion, a flexible rubber damping ring is more than just a part; it’s a silent solution to a common problem. By absorbing vibrations and reducing noise, it ensures your hydraulic system operates smoothly, protecting your equipment and reducing downtime. The time has come to embrace this silent hero in your hydraulic system – your machine will thank you.

.png)